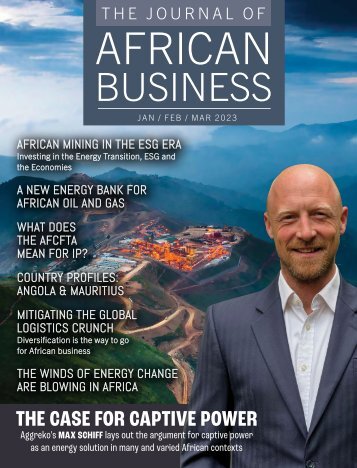

Opportunity Issue 103

- Text

- Infrastructure

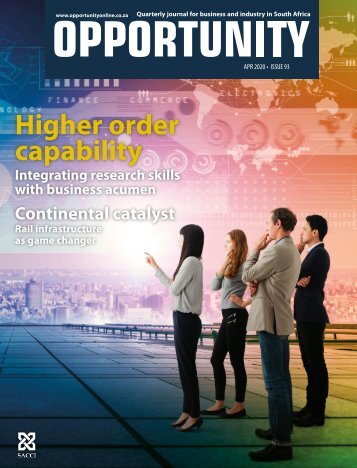

- Research

- Survey

- Business

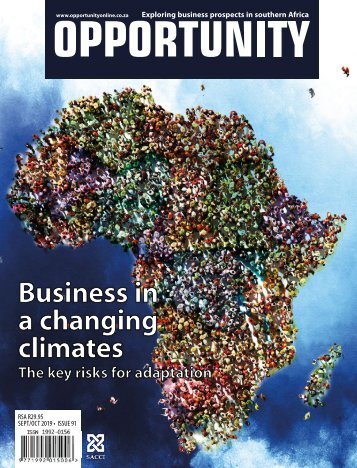

- Africa

- Investment

- Trade

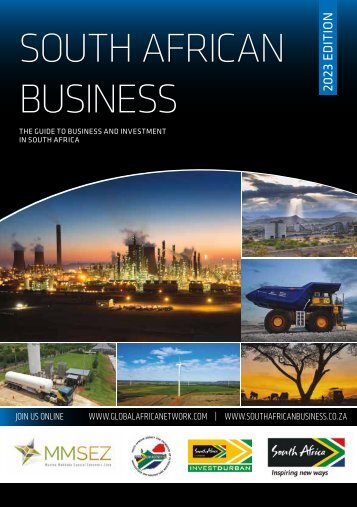

- South africa

- Green energy

- Mining

- Wwwglobalafricanetworkcom

- Samsung

- Global

- Programme

- Hydrogen

- Digital

- Businesses

- Innovation

- Economic

- Sacci

ENGINEERING M ST

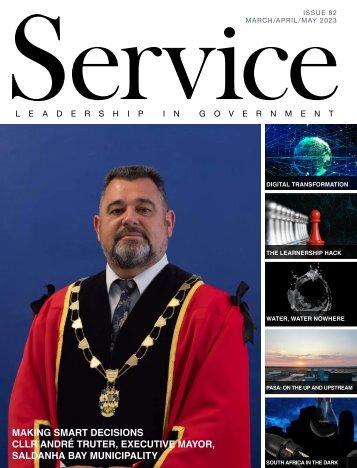

ENGINEERING M ST Steinmüller Africa’s specialised induction bending solutions benefit industry One of only two machines in Africa brings advantages to partners across South Africa. Steinmüller Africa, a specialist in the engineering and fabrication of high-pressure components, offers exclusive induction bending solutions to the South African market. Its Cojafex PB 850 induction bending machine is one of only two induction bending machines on the African continent, enabling paper and pulp, power, petrochemical and mining plants to source custom bends locally, as well as large radius, multiple or complex bends – all with quick turnaround times. Induction bending is the process whereby a straight pipe is precision-bent by a specially-engineered machine. The front of the pipe protrudes through an induction coil and is clamped into position. The induction coil is heated to a specified temperature and then the arm of the machine moves in a predetermined radius, pushing the pipe through the coil. “This is programmed into the machine upfront and is an automated process,” explains Lee Chapman, Divisional Bellows Manager – Piping, Steinmüller Africa. The automation and machine control renders a precise and top-quality pipe bend. Headers “Our Cojafex machine is capable of bending pipes between 48.3OD and 850OD with a wall thickness up to 100mm. It can create bends up to 180 degrees,” adds Chapman. Induction bending is ideal “when standard size bends are not available and custom or large radius bends are required,” states Chapman. Since it can create complex (multiple) bends without the need for welding, induction bending guarantees pipe-system integrity and a reduced maintenance requirement, making it especially well-suited to high pressure (HP) piping, steam piping and industrial piping systems. This also means it delivers a relatively low cost of ownership. In addition, if multiple bends are done at once then there is a cost saving during the erection and ongoing maintenance phases of a plant’s operation. The benefit of partnering with Steinmüller is that it offers complementary services in addition to induction bending. “There is no need to move the component between different suppliers as we are able to do all the necessary bending, welding and heat treatment in-house,” says Chapman. Using its Schlager gas furnace, Steinmüller conducts post bend heat treatment (PBHT), which ensures the pipe’s mechanical properties are restored following the bending process. In addition, Steinmüller specialises in various welding processes, enabling custom welding onto pipes. A commitment to safety and quality, backed by international expertise, has made Steinmüller Africa the fabricator of choice for some of South Africa’s largest power, paper and petrochemical companies. “Steinmüller has been carrying out induction bending for over 10 years at its facility in Pretoria and has a number of qualified bending procedures to both EN and ASME standards for safety and quality. Our in-house quality management system ensures that our products meet all the necessary international standards,” adds Chapman. Steinmüller Africa is a Bilfinger Power Africa company and is a BBBEE Level 1 company. For almost six decades, Steinmüller has provided comprehensive solutions for steam generating plants, from design through to commissioning and afterservice maintenance. Engineering design services Boiler pressure parts Commissioning, field and testing services Induction bending of HP/HT piping Heat treatment (workshop and in situ) HP Heaters Piping technology Pipe supports Plant erection services Explosive welding Enquiries: Lee Chapman, Divisional Manager, Piping, Steinmüller Africa Tel: +27 11 806 3947 Email: lee.chapman@bilfinger.com Website: www.steinmuller.bilfinger.com S in subs have bee and bro W

AKE EAM einmüller Africa (Pty) Ltd. is one of the enterprises Bilfinger Power Africa (Pty) Ltd., the South African idiary of German based Bilfinger SE. For years, we adding value to the power, mining, paper pulping der industry through comprehensive valve supply, valve maintenance and heat treatment solutions. www.steinmuller.bilfinger.com WE MAKE POWER Steinmüller Africa (Pty) Ltd. Ltd. is is one of of the the enterprises in in Bilfinger Power Africa (Pty) Ltd., the the South African subsidiary of of German based Bilfinger. Our Our presence in in the the local market, spanning 53 53 years, ORK is is testimony to to our our unrivalled expertise in in the the steam generation industry. Services offered range from the the design and manufacturing to to the the construction and maintenance of of boiler pressure parts. At At our our South African based manufacturing facilities, we we also specialise in in fabrication of of highpressure feedwater heaters, pressure vessels, pipe supports and compensators. On-site maintenance crews provide support to to the the power generation and petrochemical sectors. www.steinmuller.bilfinger.com www.steinmuller.bilfinger.com WORK Engineering design services Boiler pressure parts Commissioning, field and and testing services Bellows Headers Induction bending of of HP/HT piping Heat treatment (workshop and and in in situ) HP HP Heaters Piping technology Pipe supports Plant erection services Explosive welding Visit our stand at at the African Utility Week Expo

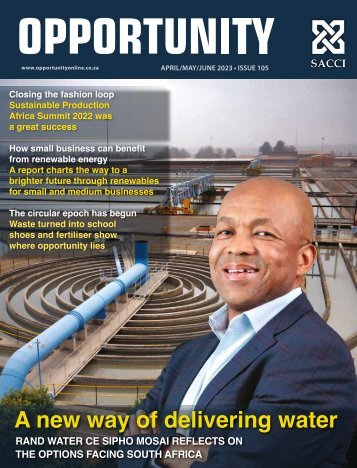

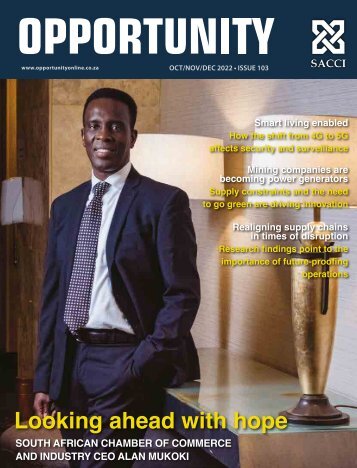

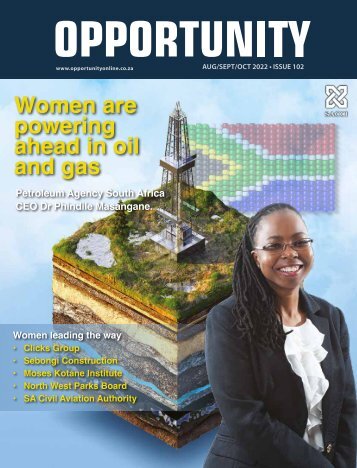

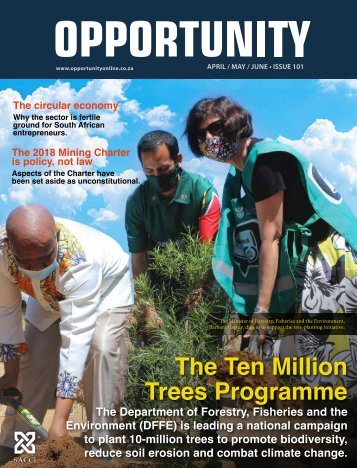

- Page 1: www.opportunityonline.co.za OCT/NOV

- Page 4 and 5: Banks find new growth in next gener

- Page 6 and 7: Contents ISSUE 103 | OCT / NOV / DE

- Page 8 and 9: News & snippets Industry insights f

- Page 10 and 11: FOREWORD Hope is the key into 2023

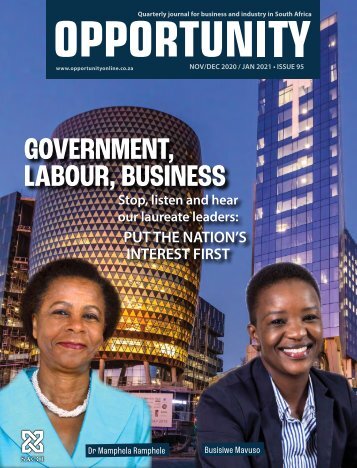

- Page 12 and 13: SACCI ANNUAL CONVENTION Company Pro

- Page 14 and 15: BETTER BUSINESS Unique offerings fr

- Page 16 and 17: SACCI Business body rolls out new i

- Page 18 and 19: Mining companies are becoming power

- Page 20 and 21: MINING AND POWER At Iduapriem Mine

- Page 22 and 23: A coal sampling and analysis compan

- Page 24 and 25: SUSTAINABLE DEVELOPMENT Energy secu

- Page 28 and 29: ENERGY PERFORMANCE Buildings must d

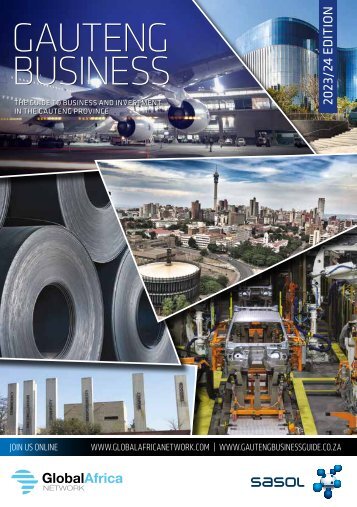

- Page 30 and 31: VAAL SEZ Reigniting the birthplace

- Page 32 and 33: VAAL SEZ Reindustrialising the Vaal

- Page 34 and 35: CLIMATE CHANGE RISK Shifting Africa

- Page 36 and 37: FOCUS The Responsible Mohair Standa

- Page 38 and 39: AGRI TECH Innovation in agriculture

- Page 40 and 41: Understanding Marine L itter and it

- Page 42 and 43: Smart living enabled Marcel Bruyns,

- Page 44 and 45: INTERVIEW Innovation is at the core

- Page 46 and 47: Why eLearning is crucial in our bra

- Page 48 and 49: UPSKILLING YOUTH AND WOMEN IN THE A

- Page 50 and 51: ECONOMIC DEVELOPMENT Samsung recomm

- Page 52 and 53: ECONOMIC DEVELOPMENT vital to rever

- Page 54 and 55: LOGISTICS Independent Ports Authori

- Page 56 and 57: SAVE TIME - REDUCE COSTS & REGISTER

- Page 58 and 59: RAIL SAFETY New railway regulations

- Page 60 and 61: SUPPLY CHAIN Customer focus is key

- Page 62 and 63: ENTREPRENEURSHIP There is hope for

- Page 64 and 65: SOCIAL ENTERPRISES Seed funding for

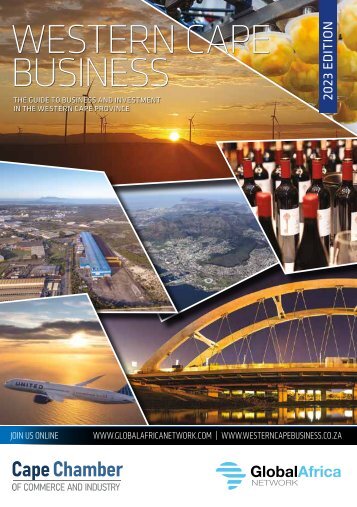

- Page 66 and 67: INVESTMENT AND TRADE Flanders is an

- Page 68: Kwa lbo Equiano 2Africa ACE Equiano

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...