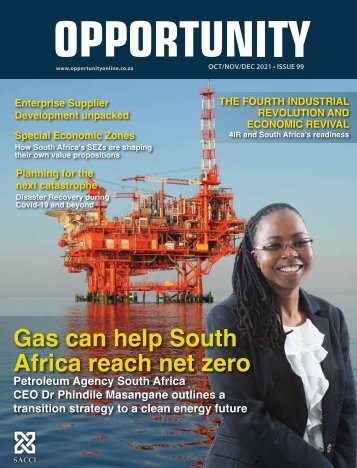

Opportunity Issue 99

- Text

- Industry

- Trade

- Investment

- Africa

- Business

- Sadc

- Sacci

- Wwwglobalafricanetworkcom

- Opportunities

- Enterprise

- Industrial

- Businesses

- Sector

- Global

- Economic

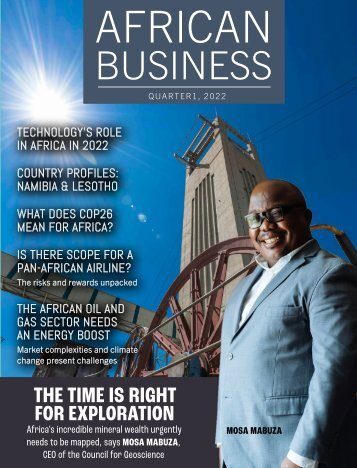

- African

DISASTER RECOVERY About

DISASTER RECOVERY About Routed Routed is a true cloud provider. Secure, robust and reliable, the Routed cloud platform is vendor neutral and offers scalable, full or hybrid cloud hosting. Engaging directly or within a channel, Routed delivers cloud and infrastructure solutions to enterprise customers, wholesale partners, resellers and affiliates. Founded in 2016 in response to a growing demand for data centre hosting solutions following the rapid growth and penetration of fast, reliable connectivity services in South Africa, Routed is led by industry veterans with over 35 years of experience in delivering and managing secure cloud and infrastructure solutions both locally and internationally. Test your Disaster Recovery plans. If your Disaster Recovery doesn’t work, it’s like paying for insurance and then not getting a payout when you claim. Disaster Recovery is not trivial to implement, but it should be easy enough to test. Your provider should have this built into their solution both technically and commercially. No-one wants to fix the roof while it is raining or change a tyre at 100km/h and businesses cannot afford to address serious technical problems in the face of a major disaster. Testing Disaster Recovery plans shows up performance and capacity issues and allows organisations to plan accordingly, which may include switching providers. Find the right skills. Anyone who is part of a Disaster Recovery team should be well organised, and calm in the face of pressure. Clearly, technical skills to operate, manage and test the environment are also required. Enterprises need to ensure they have access to these skills from their provider. Consider the costs. Although cloud-based disaster recovery solutions are designed for the larger enterprise, it is available, in scale, and therefore within the reach of smaller businesses too. Disaster Recovery should not be more than 20-30% of an organisation’s IT production budget. Keep in mind that it is not necessary to invest in capital, by purchasing the target hardware and software. Businesses can buy disaster recovery as a service and rent what is needed, based on usage. Andrew Cruise, Managing Director of Routed 46 | www.opportunityonline.co.za

Sani-touch saniwipes go Sani-touch has committed to becoming more sustainable, starting with the launch of its new green 100% recyclable saniwipes. The Sani-touch range of products is part of Infection Protection Products, a familyrun business with over 30 years of local manufacturing experience supplying detergent disinfectant and sanitising products. Their Saniwipe trolley wipes for retailers and their range of medical grade wipes for the medical industry, amongst their other offerings, have garnered them a trusted brand reputation over the years. The ongoing Covid-19 pandemic has highlighted the need for good hygiene practices, cleaning and disinfection in public spaces. When the demand for trolley wipes increased by 500% almost overnight in 2020, established wipe manufacturers like Sani-touch were unable to meet this rapid and unexpected increase in demand, and a number of new, often untested, products appeared in the market. Sani-touch, with extensive experience in the industry, realised the need to consolidate its market offering, limited its product range temporarily to concentrate on producing wipes in an eff ort to keep supermarket doors open and trading, and hospitals, clinics and blood banks protected. Although Sani-touch’s Sanispray and Medigiene sanitizers were the only high-alcohol sanitizers with the accredited SABS 490 and SABS 1853 marks in the market at the time, due to signifi cant raw material shortages these products were put on production-holds, while the manufacture of pre-saturated wipes increased drastically to keep up with demand — made possible by signifi cant investments into new machinery as well as streamlining production processes. Sani-touch’s saniwipes are historically manufactured using either an imported biodegradable wipe fabric or more cost-effective 100% recyclable, locally sourced polypropylene. As a result of its greater availability and lower cost, demand for polypropylene wipes has far exceeded that of the more environmentally friendly biodegradable wipes. As passionate environmentalists, Infection Protection Products was concerned with the high-volume increase of polypropylene now entering landfi lls and the company partnered with various recycling companies to investigate the viability of recycling its used polypropylene wipes. As a result of these investigations, Sani-touch’s saniwipes have gone green, not only providing protection from bugs and bacteria, but now also protecting the environment – one wipe at a time. Green saniwipes are manufactured using 100% polypropylene – a fully recyclable material. The wipes come in a 100% polypropylene bucket container, with a 100% polypropylene lid and catch system. Even the labels on the bucket are made from polypropylene. The used wipes have been tested to ensure they are bacteria-free and that no fl uid residual will aff ect the recycling process. All new saniwipe dispenser stands entering stores have been redesigned with smaller bin holes for the used wipes, to prevent consumers from discarding other foreign objects into the waste material receptacles. This will ensure that everything being recycled consists only of 100% polypropylene. The recycled polypropylene is used in the production of the wipe bucket catches, pallets and outdoor furniture as well as other useful items. Sani-touch is leading the way, not only in promoting sustainable practices but also by implementing less impactful and more environmentally friendly production processes which ensure that its products can be part of a sustainable circular economy. Ultimately, Sani-touch is proving that single-use products such as wipes don’t only off er outstanding infection protection but can also be environmentally neutral. brought to you by Sani-touch Infection Protection Products The steps we are taking today to control the plastic lifecycle will echo for generations to come. ANNETTE DEVENISH Marketing director, Infection Protection Products.

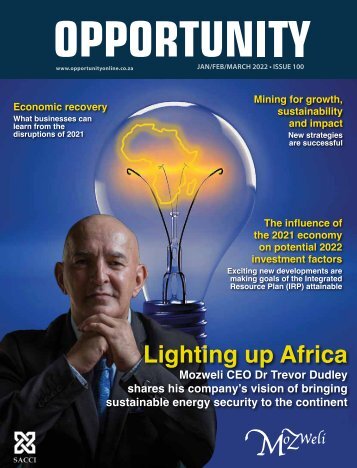

- Page 1 and 2: www.opportunityonline.co.za OCT/NOV

- Page 6 and 7: Contents ISSUE 99 | OCT / NOV / DEC

- Page 8 and 9: EDITOR’S NOTE Good news in the en

- Page 10 and 11: FOREWORD Certificates of Origin bre

- Page 12: News & snippets Industry insights f

- Page 15 and 16: OIL AND GAS _________________ The I

- Page 17 and 18: OIL AND GAS PETROLEUM SA AT A GLANC

- Page 19 and 20: " " " " " " " " " " " " " " " " " "

- Page 21 and 22: Corporate and Investment Banking Fr

- Page 23 and 24: CLI AG is an international transpor

- Page 25 and 26: TRANSPORT According to Sithole, eac

- Page 27 and 28: TRANSPORT “It was make or break t

- Page 29 and 30: SPECIAL ECONOMIC ZONES Incentives T

- Page 31 and 32: SPECIAL ECONOMIC ZONES Techno parks

- Page 33 and 34: Turn “likes” into buys with SMA

- Page 35 and 36: INTERVIEW We were adamant in buildi

- Page 37 and 38: SPECIAL ECONOMIC ZONE Inclusive gro

- Page 39 and 40: WE MAKE STEAM Steinmüller Africa (

- Page 41 and 42: FLEET MANAGEMENT Increase fuel effi

- Page 43 and 44: Beefing up your technology presence

- Page 45 and 46: TECHNOLOGY Other proposed intervent

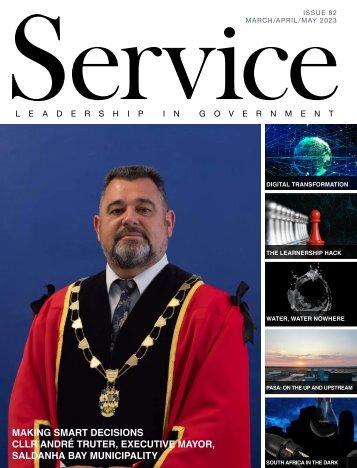

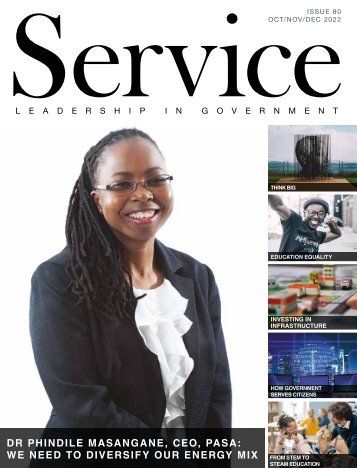

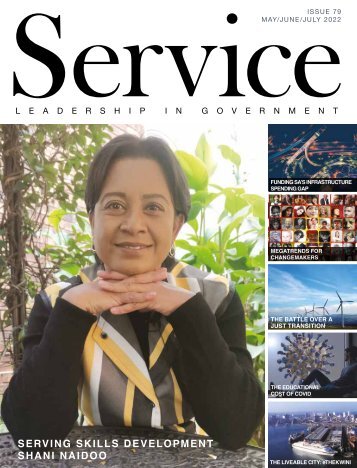

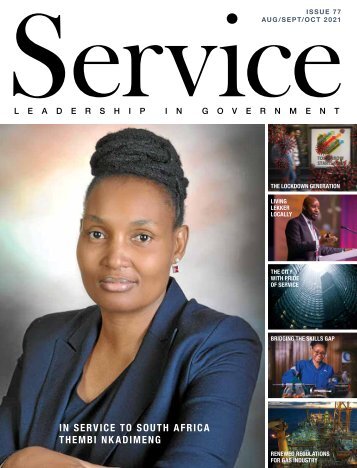

- Page 47: DISASTER TECHNOLOGY RECOVERY Planni

- Page 51 and 52: UVC disinfection luminaires Profess

- Page 53 and 54: FX FX RISK MITIGATION FOR SMES Smal

- Page 55 and 56: PPC - bridging the skills gap, one

- Page 58 and 59: INTERVIEW ENRICHING LIVES THROUGH S

- Page 60 and 61: ENTREPRENEURSHIP MultiChoice is nur

- Page 62 and 63: INTERVIEW WAYA WAYA GLOBAL CONNECTI

- Page 64 and 65: INTERVIEW Patson Phala started out

- Page 66 and 67: AGRICULTURE TECHNOLOGY IS REDUCING

- Page 68 and 69: SMME FUNDING Old Mutual’s Masisiz

- Page 70 and 71: FOCUS The Responsible Mohair Standa

- Page 72: Atlantis Special Economic Zone Afri

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...